Introduction to Michael Balle & Freddy Ballé

Michael Balle and Freddy Ballé are two of the most renowned experts in the field of Lean Management. They are the authors of the book "The Lean Manager," which is considered a must-read for anyone interested in implementing Lean principles in their organization. Balle and Ballé have extensive experience in Lean Management, having worked with numerous companies around the world. In this article, we will explore their principles and practices of Lean Management.

The Lean Manager: Principles and Practices

What is Lean Management?

Lean Management is a management philosophy that focuses on creating value for the customer while minimizing waste. It is based on the Toyota Production System, which was developed by Taiichi Ohno and Eiji Toyoda in the 1950s. The goal of Lean Management is to create a culture of continuous improvement by eliminating waste, improving quality, and increasing efficiency.

The Five Principles of Lean Management

Balle and Ballé identify five principles of Lean Management: value, value stream, flow, pull, and perfection. The first principle, value, refers to understanding the needs of the customer and creating products and services that meet those needs. The second principle, value stream, involves mapping out the entire process of delivering a product or service, from start to finish. The third principle, flow, is about creating a smooth and efficient flow of work through the value stream. The fourth principle, pull, involves producing products and services only when they are needed, rather than producing them in advance. The fifth principle, perfection, is about continuously improving the value stream to eliminate waste and increase efficiency.

The Role of the Lean Manager

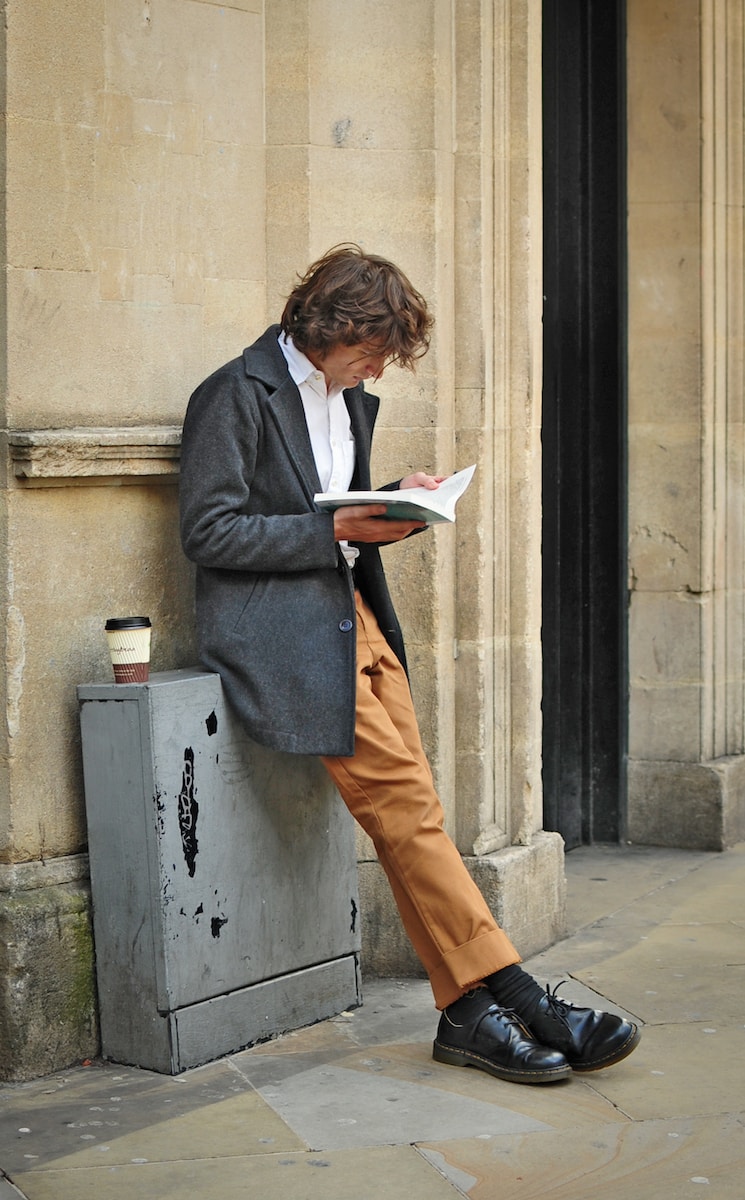

The Lean Manager is responsible for leading the implementation of Lean principles in an organization. This involves creating a culture of continuous improvement, identifying and eliminating waste, and improving quality and efficiency. The Lean Manager must also be a coach and mentor to employees, helping them to understand and embrace Lean principles.

The Lean Management Toolkit

Balle and Ballé provide a toolkit for Lean Managers, which includes tools such as value stream mapping, kaizen events, and visual management. Value stream mapping is a tool for identifying waste and inefficiencies in the value stream. Kaizen events are short-term projects focused on improving a specific process. Visual management involves using visual cues to communicate information about the status of work and identify problems.

The Benefits of Lean Management

The benefits of Lean Management are numerous, including increased efficiency, improved quality, reduced waste, and increased customer satisfaction. Lean Management also creates a culture of continuous improvement, which can lead to innovation and growth.

Conclusion

Michael Balle and Freddy Ballé’s book "The Lean Manager" provides a comprehensive guide to implementing Lean principles in an organization. Their principles and practices of Lean Management are based on the Toyota Production System and have been proven to be effective in numerous companies around the world. By creating a culture of continuous improvement, eliminating waste, and improving quality and efficiency, organizations can achieve significant benefits from Lean Management.